Non-circular Flange Design. Previous knowledge of this subject is not required to attend to the course.

11 How To Design Nonstandard Flanges On Standard Nozzles Autopipe Wiki Autopipe Bentley Communities

Modulus of elasticity at atmospheric temp.

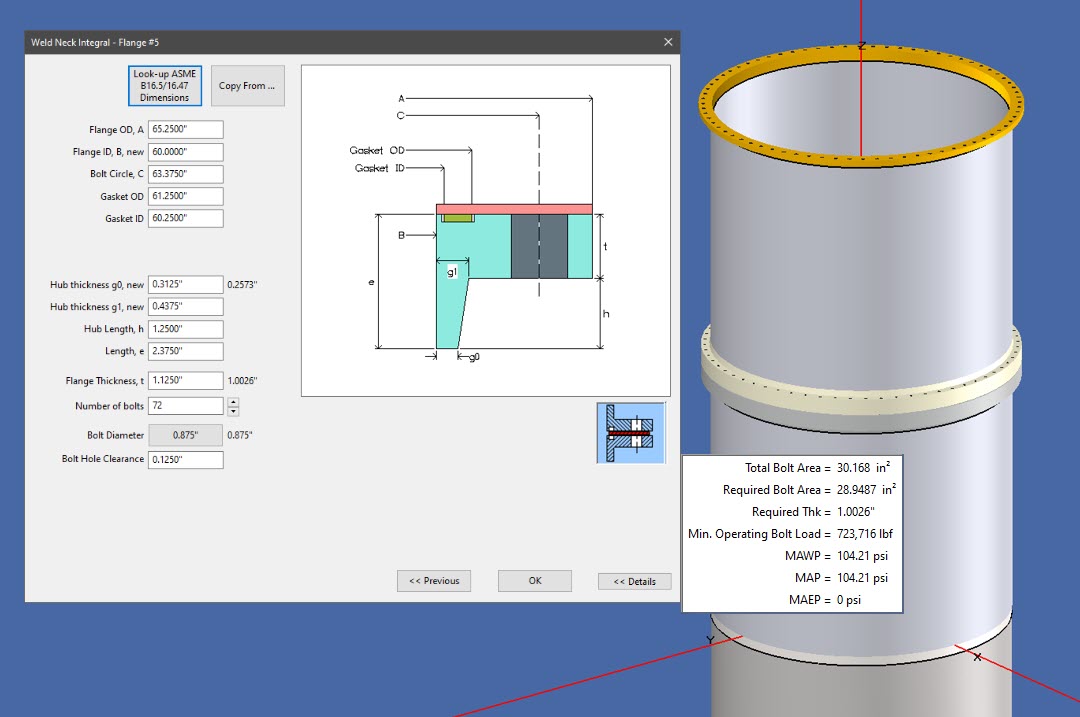

. Currently integral pipe flanges of all types with flat or ring type joint gaskets may be analysed. This method is the most commonly used method in many international pressure vessel design codes including the use of gasket coefficients for flange strength. In the Body Flange Dialog there is a Button to retrieve the dimensions of a Standard Flange see below.

Salvar Salvar Ring Flange Calculation para ler mais tarde. __Non-Contact Resistance and Capacitance on-line Measurement of Lubrication Oil Film in Rolling. April 19th 2019 - Non standard flanges will only be used in cases where pressure temperature and size requirements exceed the capabilities of standard flanges Keep in mind that non standard flanges require calculation design and special manufacturing.

9-FLANGES DESIGN OF NON-STANDARD FLANGEpdf. Non ASME standard flange design. Note not a better flange but a cheaper one.

Types of flange and gasket analysed. Alternatively flange may be qualified for B313 per 30472 a extensive successful service. 0 notas 0 acharam este documento útil 0 voto 483 visualizações 3 páginas.

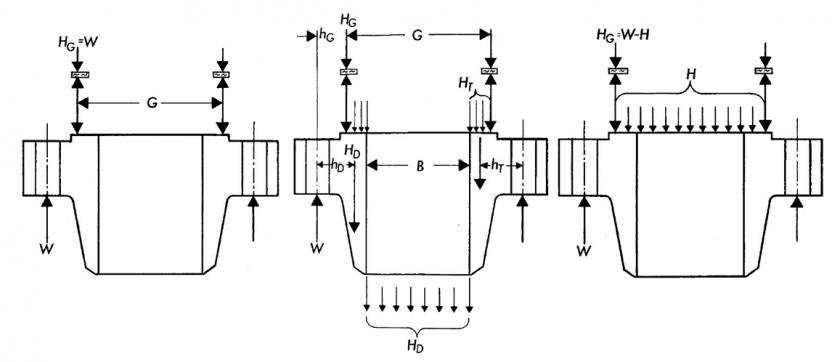

Items highlighted in Blue are information from drawing. But often there is a requirement for designing non-circular flanges particularly ovalelliptical type flanges which are integral part of valvesthough the above appendix deals with non. Fsup1 hub stress-correction factor for integral flanges when greater than 1 this is the ratio of the stress in the small end of hub to the stress in the large end for values below limit of figure use fsup1 1.

Welcome to this interactive flange bolting calculator from HYTORCThe program computes recommended torque values bolting patterns tool selection and pump pressure settings for standard ASME B165 and API 6A flanges under normal assembly conditions. Gasket OD 1775 Gasket ID 1625 Gasket m 3 Gasket y 10000. Various Sizes For Your Spec Needs.

We have to proceed a design calculations as per ASME code Section VIII Division 1-Mandatory Appendix 2 Rules for Bolted Flange Connections with Ring Type Gaskets about 10 pages of detailed calculations per flange integral loose and optional type and blind flange shall be carried out in accordance with ASME UG-346 6 pages. Root diameter d b. F factor for integral-type flanges.

The principal design code for the establishment of pipeline and piping flange stresses is ASME VIII Division 1 Appendices 2 P and S which forms the basis for the calculations in the flanges calculator. Otherwise buy apiece of software provided you bought and read the Code. Then we produced the special flanges according to their requirement.

The flange calculator includes a database of 600. Diameter of Bolts inches Bolt Circle inches 14. I suggest you make one your own so you understand what youre calculating.

Calculation design selection manufacturing safety quality and maintenance of systems and equipment in industrial processes. The traditional bolt flange design method is based on TaylorForg. Design factors allowed for.

Non-standard flange is a kind of flange relative to the national standard or some foreign standards. Pressure external bending and axial forces at the flange are all taken into account in the program detail right of ring joint dimensions used as part of the input data. Most true flange design programs will start with a small bolt typically 34 and determine whether a sufficient.

Universal engine which allows to add any new algorithms without breaching the programs operational logic. Allowable stress at atmospheric temp. 16 Bolts x 1 dia on a 2025 BCD C r.

They indicate the application service the datathe specification and the drawing. Inside Diameter B 1600 Outside Diameter A 22 Thickness t 175 Hub radius r 0375 Pipe thickness g0 075. Smaller bolt diameters will indeed generally yield a smaller more compact flange it is generally preferred.

One is that the parts in the flange connection structure must have enough strength. For Non-Standard Flanges. This course is intended for graduates or soon to be designers freelancers technicians and engineers involved in.

No matter what kind of flange its design strength calculation method can include two basic problems. Non standard ASME Flange Design Calculations Excel sheet for Pressure Vessel. Waters method is established on the basis of online elastic plate and shell theory of non-standard flange design calculation method whether it is internal pressure flange or external pressure flange in addition to the flange moment calculation formula is different according to the flange ring and cylinder or including tapered neck connected to the degree.

ASME Code VIII-1 is based on this method. Flange qualified for B313 service per 30451 b using ASME BPVC Section VIII Division 1 App2. ASME Section VIII Division 1 Appendix 2 deals with the circular type flange design.

Concept of program operation Four primary rules of program construction have been adopted. SnTMan Mechanical 4 Apr 18 1419. ASME specification VIII-1 has basically not changed much since 1940.

Internal design pressure P. Items highlighted in Orange are information estimated by engineer. Allowable stress at design temp.

Non-standard flange is usually used for customers special requirement. LT-CHIYODA LIMITED FLANGES DESIGN OF NON STANDARD FLANGE NON-STANDARD TABLE OF CONTENTS Introduction Type of Flanges Classification of flanges based on Pressure temperature rating Type of Flange faces Gasket and their properties Bolting data as per TEMA Forces acting g on a flange g Design of Loose Ring Flange Design of Weld Neck. Diameter of Flange inches No.

FsubL factor for loose-type flanges. API ANSI BS and MSS standard pipeline and piping flanges ranging from ½ inch to 48 inch and an independent. Use this to calculate the appropriate bolt area and get a reasonable size for the flange.

2 For the design of non-standard flanges without flat gaskets the influence of external loads on bolts and flange moments can be dealt with based on ASME VIm-2 2019. Second the connection itself must be guaranteed to seal. Modulus of elasticity at design temp.

However a separate analysis for the non standard flange can be performed using the component design option and designing a custom flange. Ad Custom Flange Design Fabrication. Manian Industrial OP 26 Dec 00 1052.

Torque calculations are based on the simplified formula explained in the current version of. Universal user interface which changes only if there are differences in particular calculation standards.

Flange Calculations According To En 1591 1 Youtube

Non Standard Flanges Asme Viii Arveng Training Engineering

How To Calculate Blind Flange Thickness Www Steeljrv Com

Appendix 2 Asme B16 5 16 47 Flange Design Codeware

Analysis On Design And Calculation Method Of Pressed Loose Flange China Piping Solution Supplier China Piping Solution Supplier

0 comments

Post a Comment